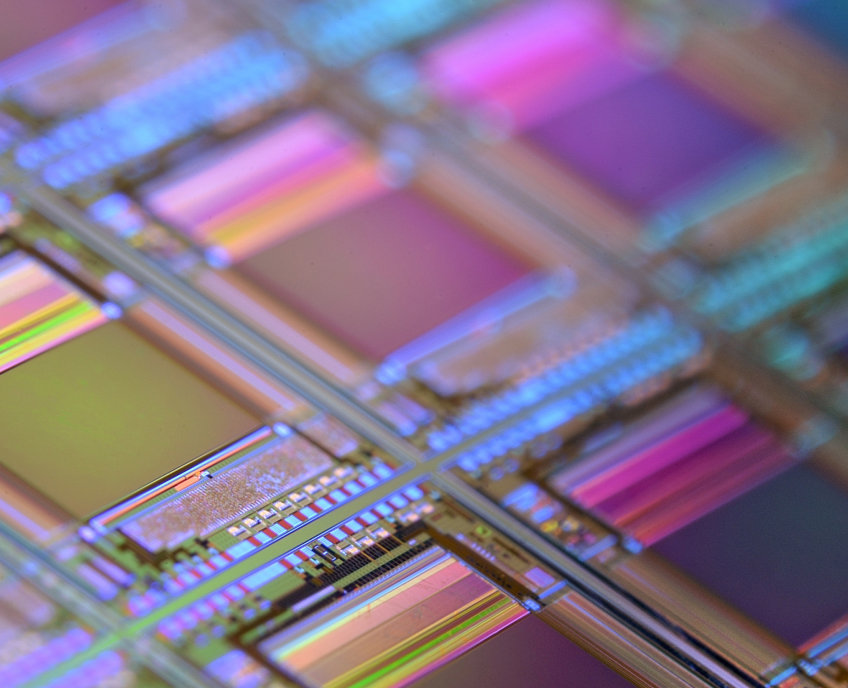

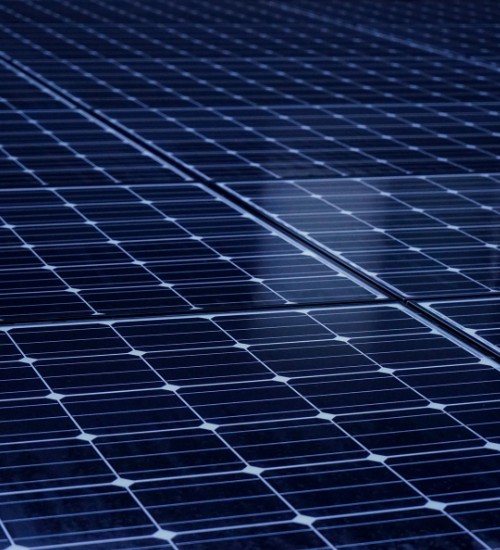

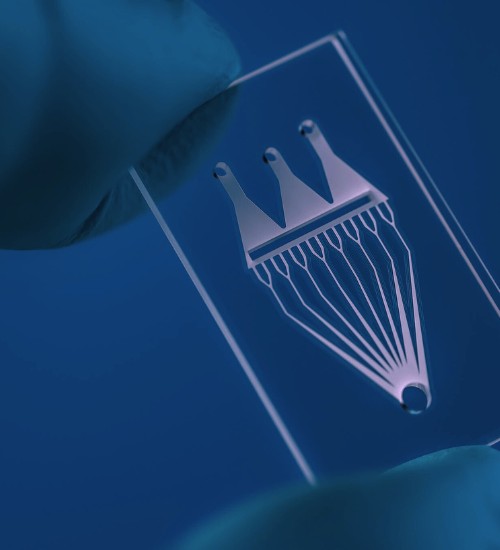

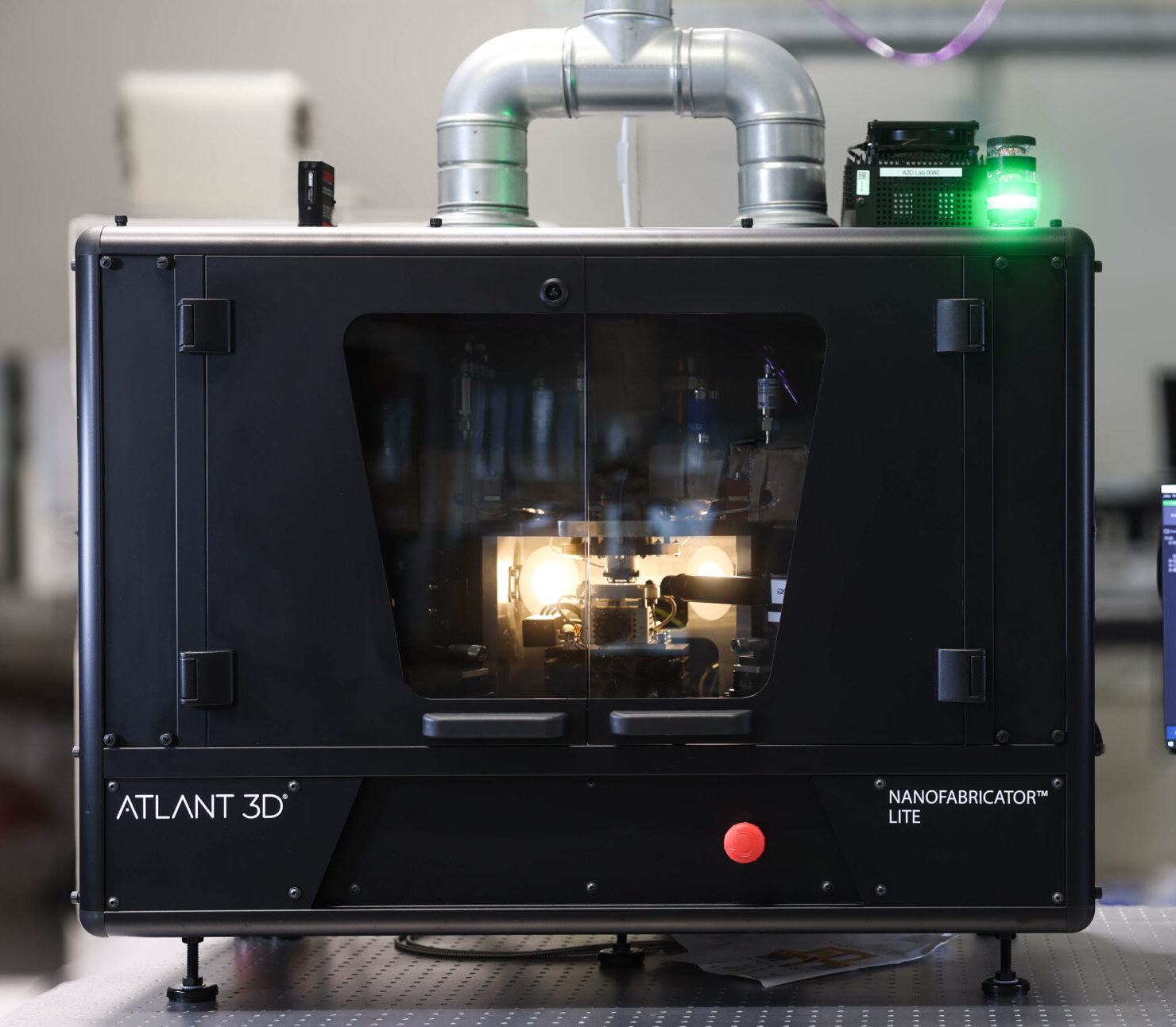

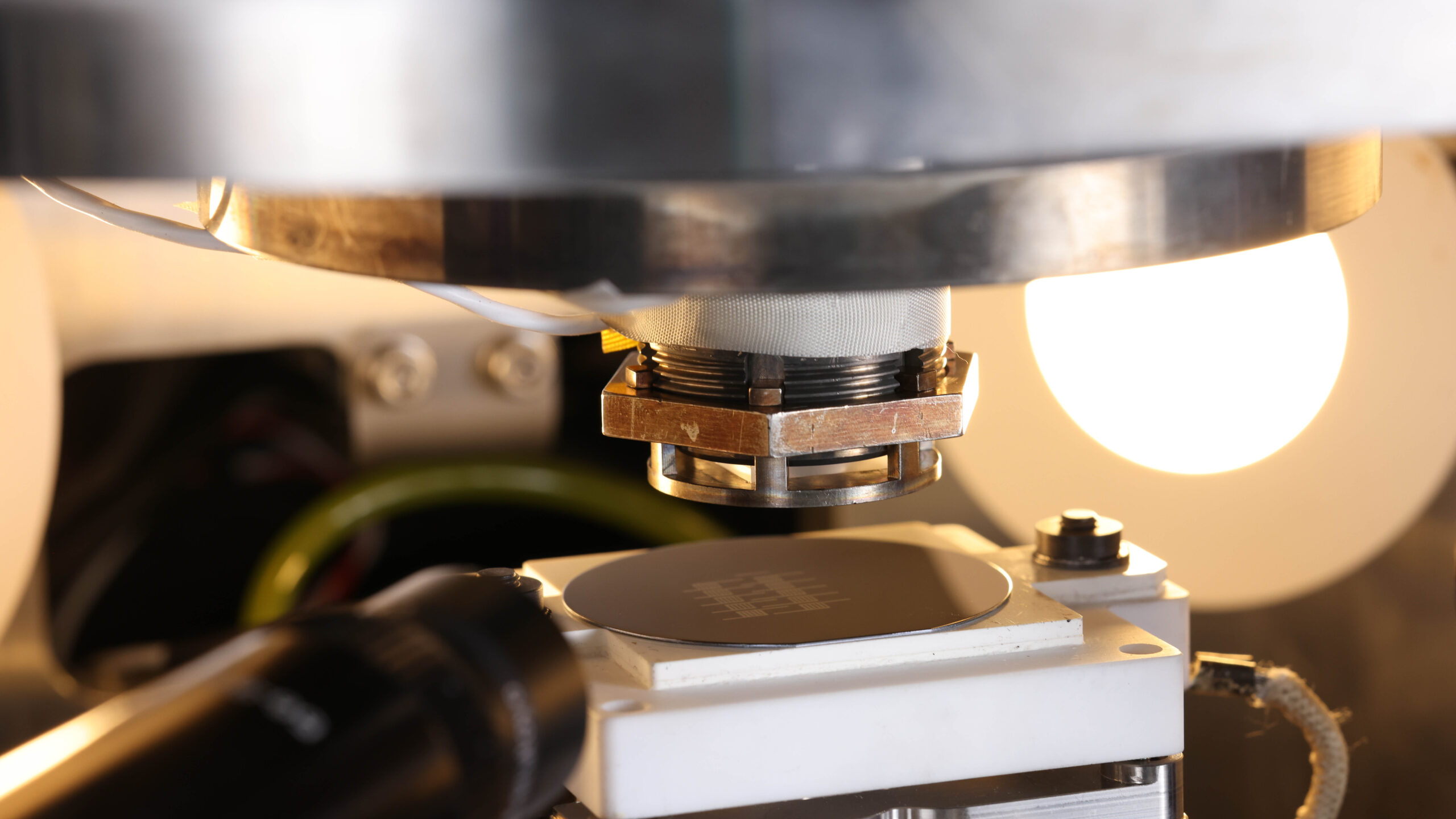

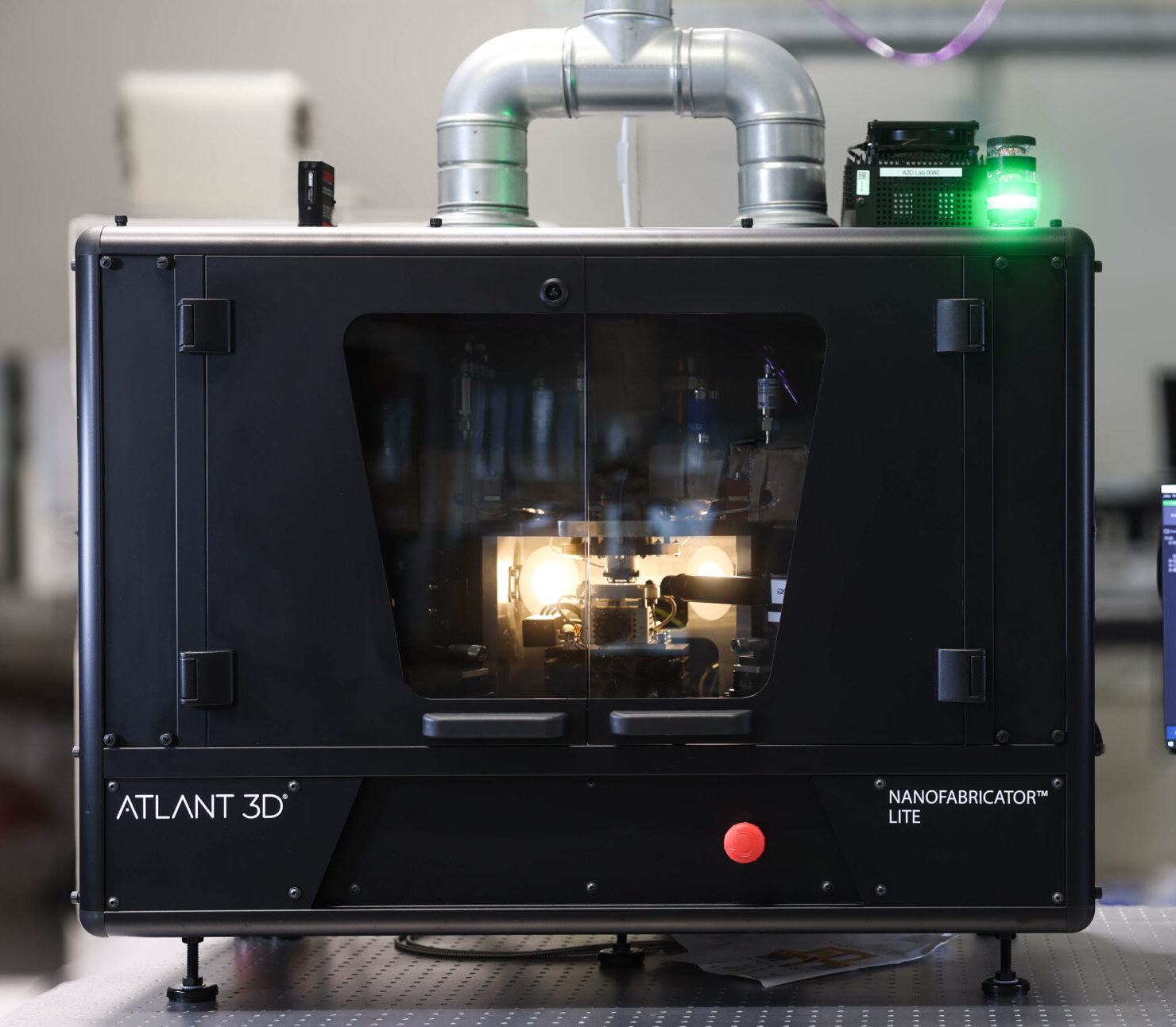

Move directly from design to functional prototype in one step. Build complexdevices like gas sensors and MIM capacitors without multiple machines or process steps. Test different material combinations and structures rapidly to optimize device performance. Move directly from design to functional prototype in one step. Build complexdevices like gas sensors and MIM capacitors without multiple machines or process steps. Test different material combinations and structures rapidly to optimize device performance. Move directly from design to functional prototype in one step. Build complexdevices like gas sensors and MIM capacitors without multiple machines or process steps. Test different material combinations and structures rapidly to optimize device performance. Our Direct Atomic Layer Processing technology uses proprietary microchemical reactors to deposit materials exactly where needed, building complex structures one atomic layer at a time. Think of it as 3D printing at the atomic scale—precise, controlled, and capable of creating structures that were previously impossible to manufacture. Unlike traditional fabrication methods that require multiple steps, masks, and cleanrooms, DALP® technology directly prints materials atom by atom. This means you can: 2-week process 1-day process Create multilayer structures atom by atom in a single process step. Uniform coatings on 90° walls, deep cavities (up to 60 microns), Fabricate advanced devices like Bragg mirrors, MIM capacitors, “We are excited to leverage the unprecedented capabilities of the ATLANT 3D Nanofabricator Lite (NFL) to explore atomic-scale engineering of complex thin-film materials and interfaces. This cutting-edge tool will play a pivotal role in advancing our research into next-generation batteries, materials for analog neuromorphic computing, high-power GaN electronics, and active layers for perovskite solar cells, pushing the boundaries of what’s possible in material science and device innovation.” Assistant Professor, Dep. Of Physics “ATLANT 3D’s DALP technology completes our inkjet process by enabling precise, localized conformal functionalization of nanostructures and MEMS with metals and metal oxides. This capability allows us to integrate multiple materials into a single sensor platform, significantly boosting the performance and detection capabilities of our electrochemical sensors, making it an essential component of the sensor technology solutions developed in AMUSENS.” Lead R&T Associate at LIST, “ATLANT 3D’s direct deposition capabilities have allowed us to overcome the design constraints of lithography, creating novel device designs for electronic devices and sensors, even on complex surfaces. The integration of multiple materials in a single sensor platform has vastly improved our capabilities, making it an invaluable asset in our research.“ Scientific Researcher, Institute of Electrical Engineering, Slovak Academy of Sciences “ATLANT 3D’s innovative μDALP™ technology has been pivotal in revolutionizing edge passivation and enabling precise material deposition for copper electroplating in solar cells. Their ability to selectively and efficiently deposit multifunctional layers has opened new pathways for cost-effective, high-efficiency solar cell production, supporting our mission to drive the renewable energy transition.” Group Leader, DTU Electro, Solar Photovoltaics Systems Group Interested in learning more? View detailed specifications Precision Meets

Progress, Atom by Atom. Key Application Areas

Material Research & Development

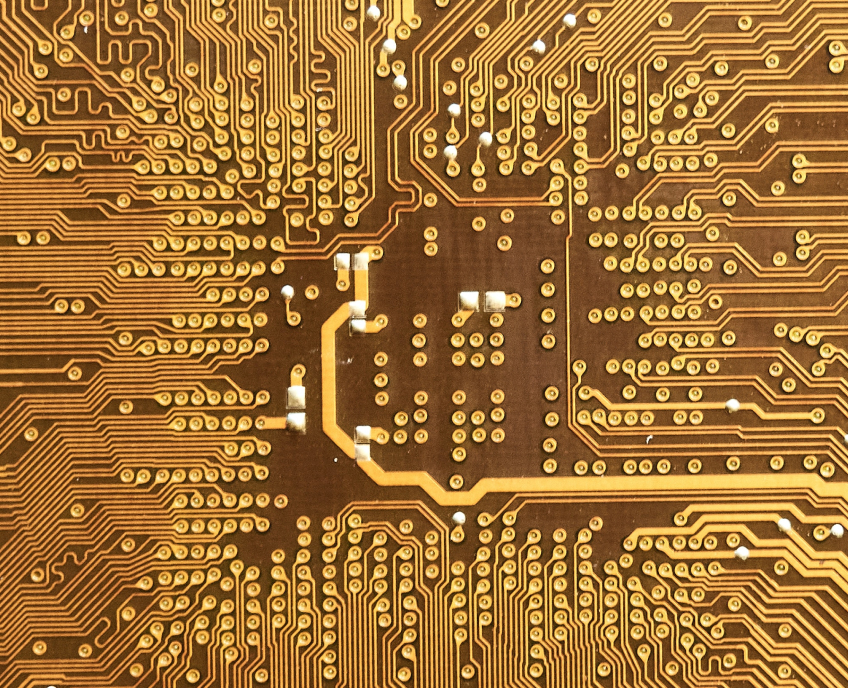

Advanced Device Prototyping

Next-Generation Electronics

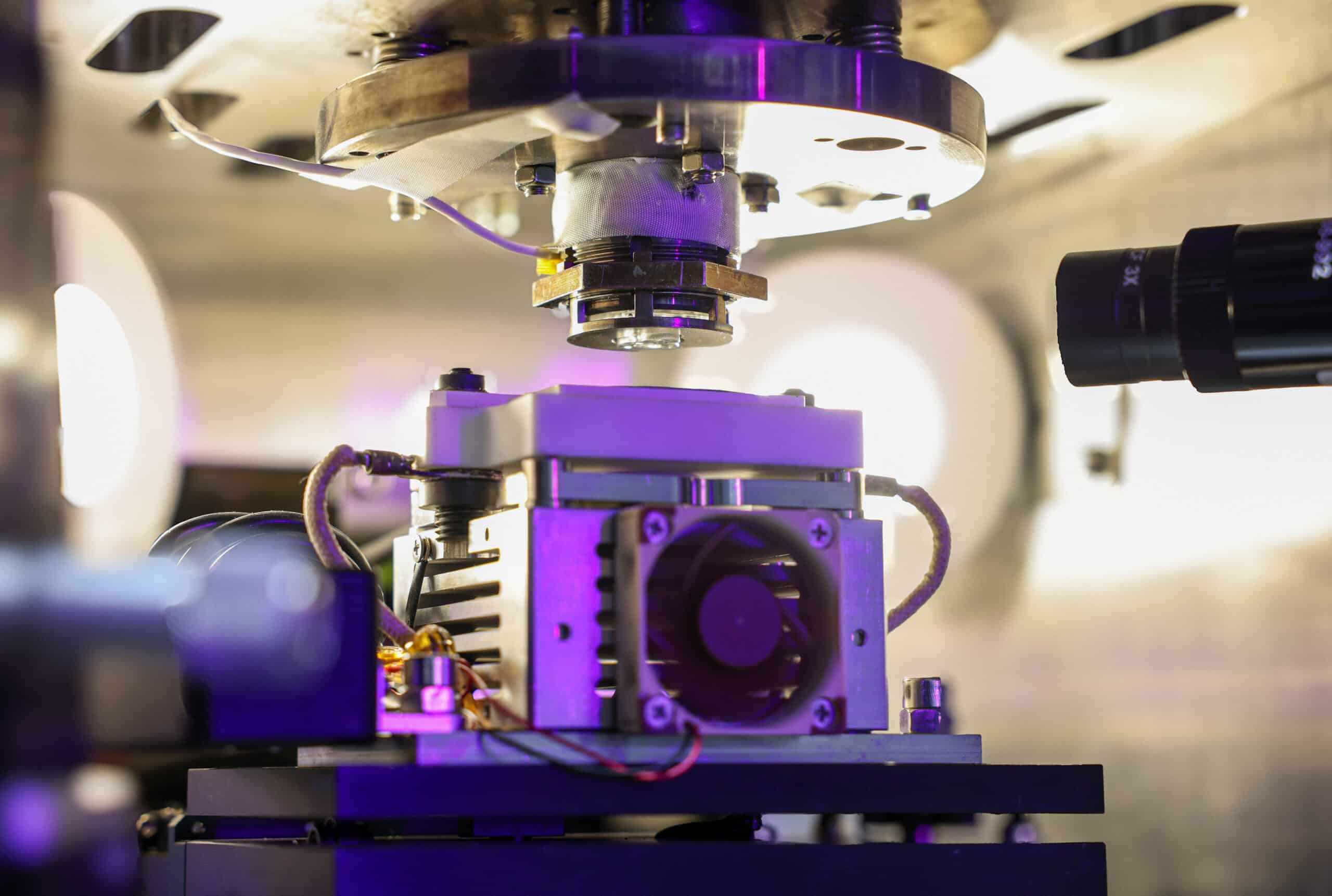

DALP® Technology: Precise Control

at the Atomic Scale

How it Works

Why its Better

Us vs Them

Traditional Method

Multiple machines

Complex clean room setup

Limited material combinations

Fixed patterns

DALP® Technology

Single tool

Benchtop operation

Multi-material capabilities

Dynamic, adjustable designs

Main Benefits Grid

Precision

Speed

Flexibility

Efficiency

Featured Applications

Technical

Specifications Highlight

and intricate nanostructures.

and vertical interconnections.

Testimonials

Alexander C. Kozen,

Renaud Leturq,

Boris Hudec,

Peter Behrensdorff Poulsen

Ready to Turn Months of Research into Days?

and features of the Nanofabricator™ Lite. Let’s discuss how Nanofabricator® Lite can support your unique research goals